EdgeShield Drip Edge System

Metal Panel Systems’ EdgeShield Drip Edge System is designed to effectively terminate self-adhered or mechanically fastened membrane roofing systems and can be used above gutters as well. This system is compatible with many varieties of roof membranes including TPO, EPDM, BUR, and Modified Bitumen. The EdgeShield Drip Edge System has been tested to meet ANSI/SPRI ES-1 requirements for wind uplift and is compliant with the International Building Code. Click here for more information about ANSI/SPRI ES-1.

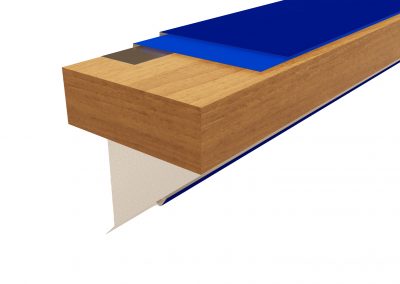

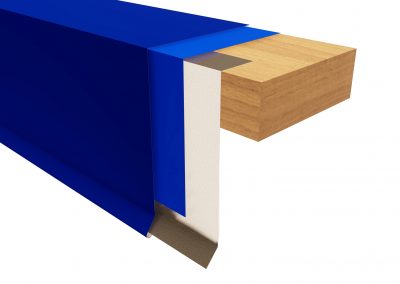

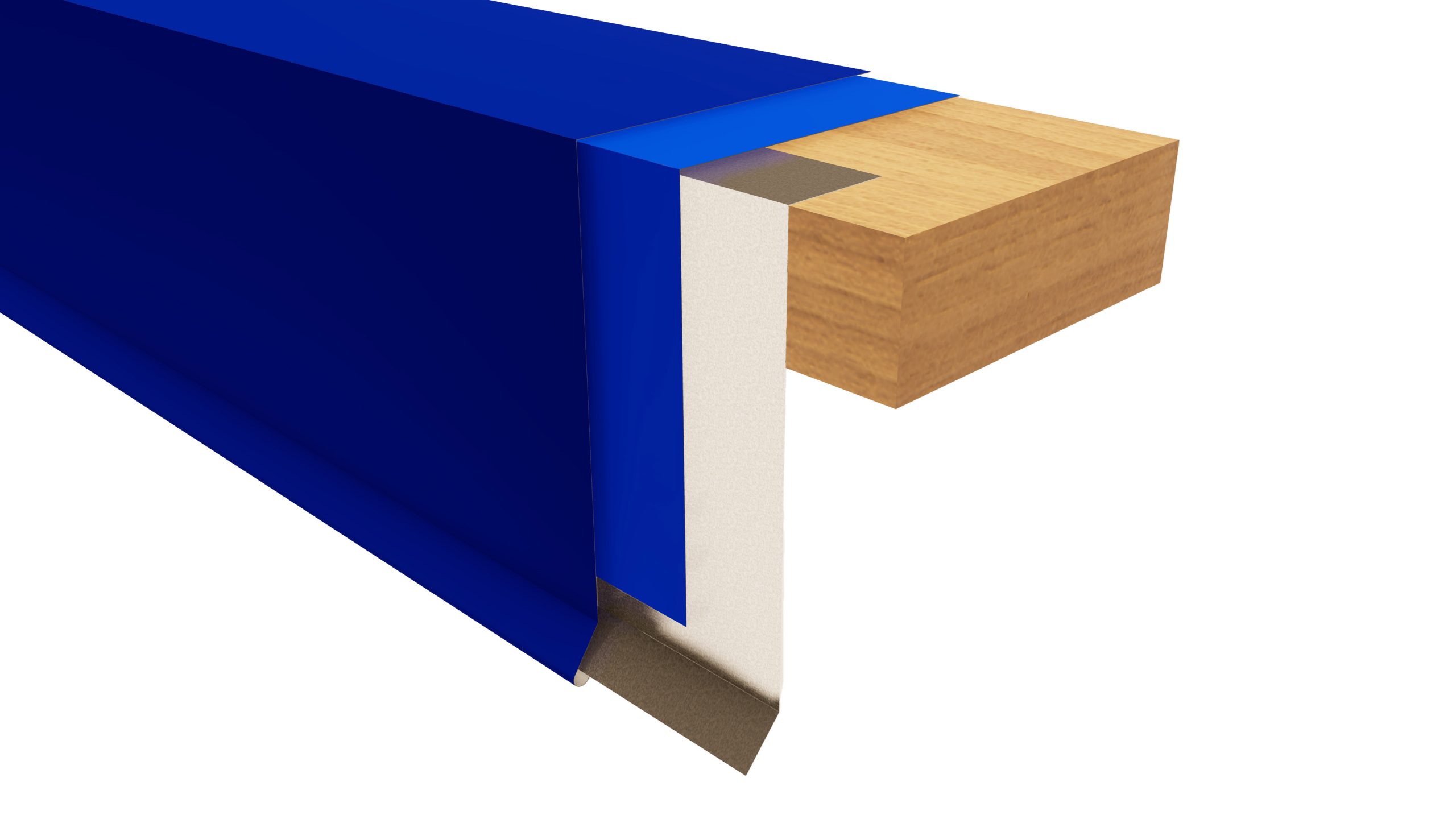

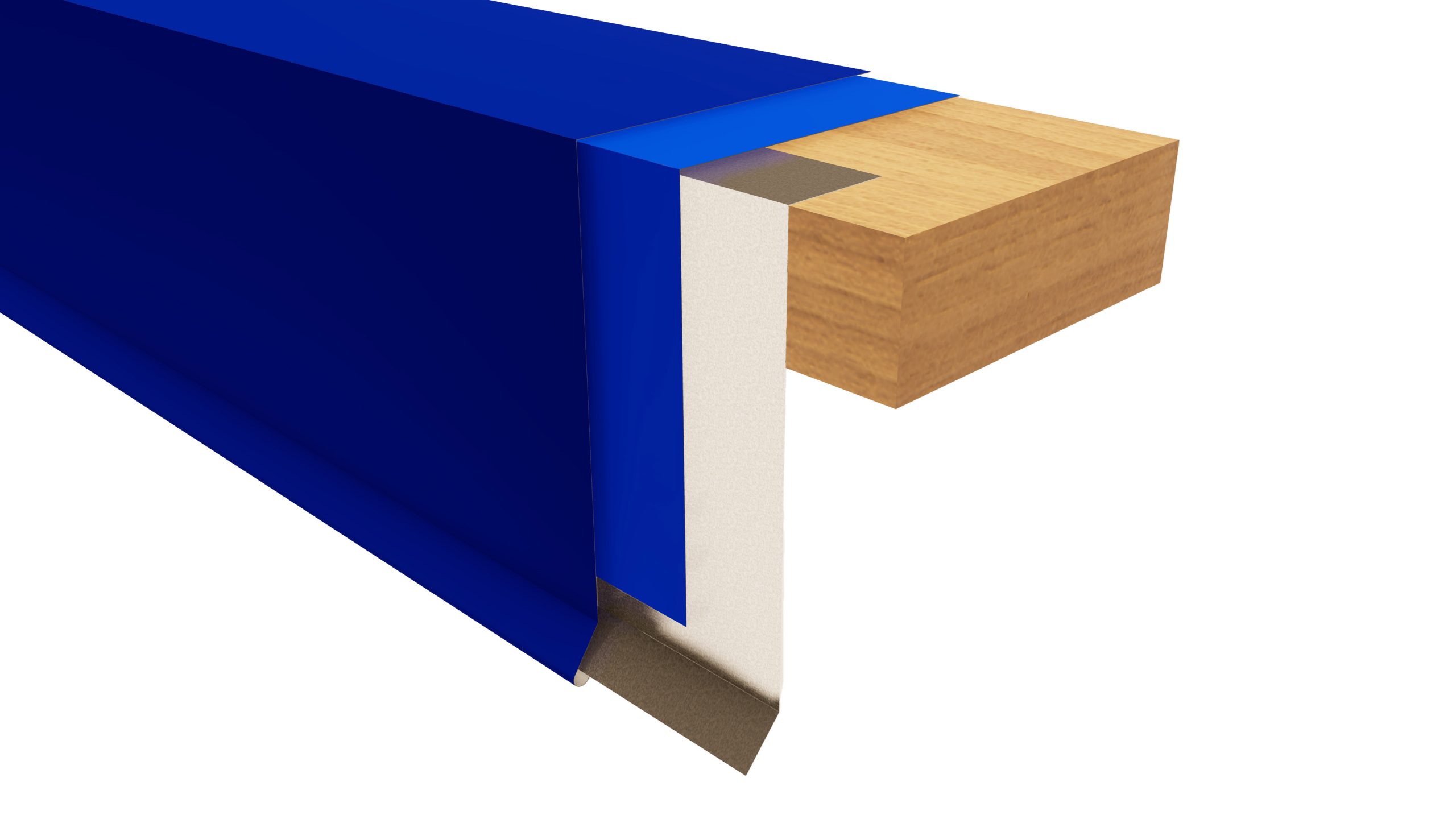

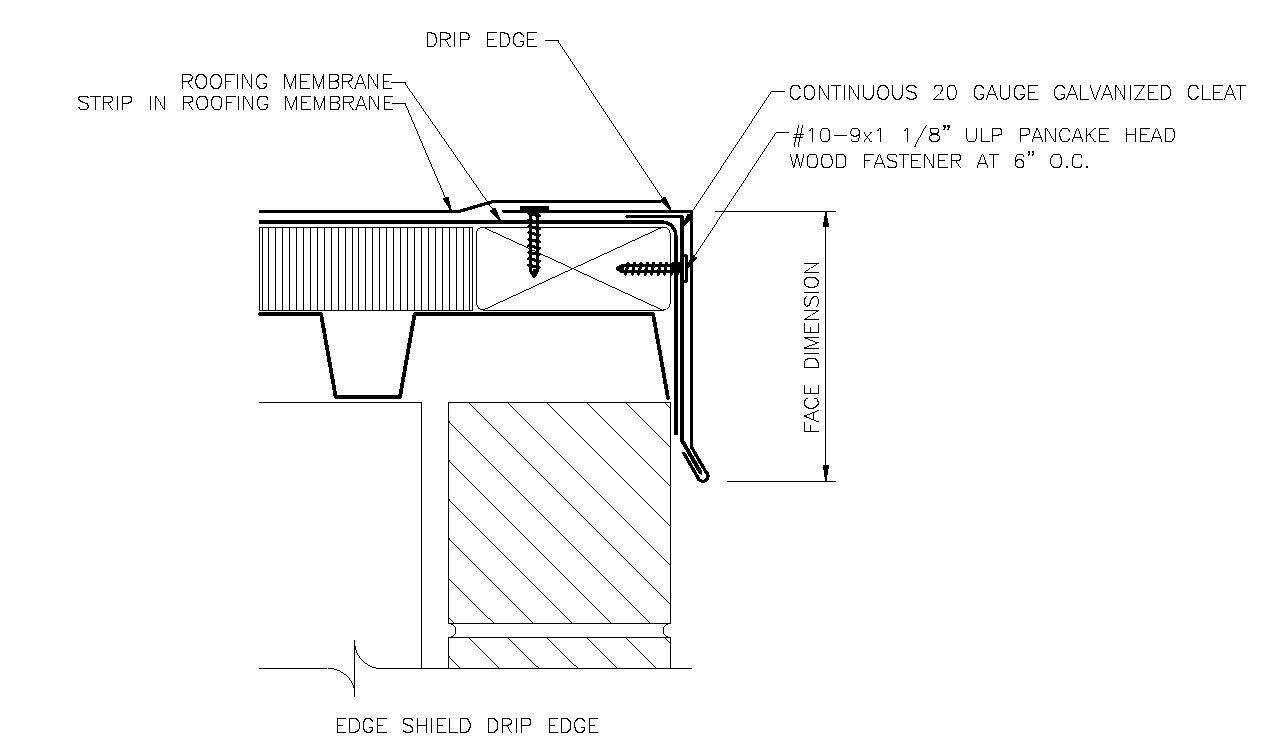

The EdgeShield Drip Edge System is easy to install for contractors and meets design criteria for specifiers. This two-piece drip edge system consists of a continuous 20 gauge cleat that is anchored to a wood nailer with a ring shanked nail or low profile screw. A section of prefinished metal with an outward projecting lower edge (to divert water from other building components) completes this system.

Metal Panel Systems’ EdgeShield Drip Edge System is designed to effectively terminate self-adhered or mechanically fastened membrane roofing systems and can be used above gutters as well. This system is compatible with many varieties of roof membranes including TPO, EPDM, BUR, and Modified Bitumen. The EdgeShield Drip Edge System has been tested to meet ANSI/SPRI ES-1 requirements for wind uplift and is compliant with the International Building Code. Click here for more information about ANSI/SPRI ES-1.

The EdgeShield Drip Edge System is easy to install for contractors and meets design criteria for specifiers. This two-piece drip edge system consists of a continuous 20 gauge cleat that is anchored to a wood nailer with a ring shanked nail or low profile screw. A section of prefinished metal with an outward projecting lower edge (to divert water from other building components) completes this system.

Diagram

Click to view full product image.

More Information

- Applicable with most roofing systems

- Installation with continuous 20 gauge galvanized cleat which is designed to be thicker than the finished metal

- Pre-punched holes to ensure proper fastener placement

- Meets ANSI/APRI ES-1 standard

- International Building Code compliant

- Concealed splice plates are also available

- Flange dimension is custom fabricated by Metal Panel Systems to suit roofing system requirements

- Standard finish is PVDF fluoropolymer coating in 30 standard colors

- System includes a 35 year finish warranty

The material thickness options include the following:

- 24 gauge (0.63 mm) galvalume

- 22 gauge (0.76 mm) galvalume

- 24 gauge (0.063 mm) stainless steel

- .032” (0.8 mm) aluminum

- .040” (1.0 mm) aluminum

- .050” (1.2 mm) aluminum

- .063” (1.5 mm) aluminum

FINISH OPTIONS include:

- Standard Kynar 500 colors (see color chart for availability)

- Custom Kynar colors

- Galvanized steel or “paint grip”

- Mill finish aluminum

- Anodized aluminum

- 2B mill finish stainless steel

*Aluminum & Copper available in limited quantities, please call for further availability